Spark Ignition Engine Calibration

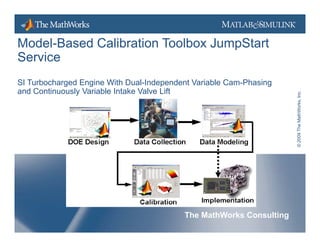

- 1. Model Based Model-Based Calibration Toolbox JumpStart Service SI Turbocharged Engine With Dual-Independent Variable Cam-Phasing and Continuously Variable Intake Valve Lift orks, Inc. © 20 The MathWo 009 The MathWorks Consulting

- 2. Course Problem Statement Given a 2.2L turbocharged 4-valve DOHC spark ignition engine with dual-independent dual independent variable cam phasing and continuously variable intake valve lift control Maximize Torque across the speed/load range of the engine subject to the following constraints: Turbocharger speed less than 160,000 RPM Engine-out exhaust temperature less than 840C AFR constrained to stoichiometry in a user-specified speed/load region hWorks, Inc. Produce corresponding optimal calibration tables in speed and load for Best spark timing © 2009 The Math Best intake cam advance angle Best exhaust cam retard angle Best AFR Best feed-forward intake valve lift position Best feed-forward variable geometry turbocharger vane position percent 2

- 3. Preview of Course Calibration Results hWorks, Inc. © 2009 The Math Spark Advance 3

- 4. Preview of Course Calibration Results hWorks, Inc. © 2009 The Math Intake Cam Advance 4

- 5. Preview of Course Calibration Results hWorks, Inc. © 2009 The Math Exhaust Cam Retard 5

- 6. Preview of Course Calibration Results hWorks, Inc. © 2009 The Math Intake Valve Lift 6

- 7. Preview of Course Calibration Results hWorks, Inc. © 2009 The Math VGT Vane Open Fraction 7

- 8. Preview of Course Calibration Results hWorks, Inc. © 2009 The Math Air/Fuel Ratio 8

- 9. Test Configuration I/O of Turbocharged 2.2L DOHC Engine with Dual-Independent Continuously Variable Cam Phasing (DIVCP) and Continuously Variable Intake Valve Lift (CVIVL) Intake VCP Brake Torque Exhaust VCP Spark Advance Turbocharger Speed RPM Intake Manifold Pressure AFR Exhaust Temperature Intake Valve Lift VGT Vane Fraction Load L d hWorks, Inc. Closed Loop Closed-Loop © 2009 The Math Load Command Load Controller Temperature-Limited AFR and Spark Control AFR Command 9

- 10. Model Configuration I/O of Turbocharged 2.2L DOHC Engine Model with Dual-Independent Continuously Variable Cam Phasing and Continuously Variable Intake Valve Lift Table RPM Brake Torque Objective Breakpoints Load Exhaust Temperature Constraints Intake VCP Turbocharger Speed VGT Open Fraction Optimal Tables Exhaust VCP Intake Valve Lift AFR Intake Manifold Pressure hWorks, Inc. Spark Advance Optimal Tables Auxiliary Table © 2009 The Math Maximize Torque subject to exhaust temperature, turbocharger speed, and user-specified AFR Constraints 10

- 11. MBC Toolbox Calibration Process DOE Design Data Collection Data Modeling hWorks, Inc. © 2009 The Math Calibration Implementation 11

- 12. Agenda Introduction Design of experiments Loading and sorting data Building models of engine responses hWorks, Inc. Producing optimized calibrations © 2009 The Math Review 12

- 13. Review Merged Experiment © 2009 The Math hWorks, Inc. 13

- 14. Temperature Limited Temperature-Limited AFR and Spark Control Method 840C Exhaust Temp Spark Retard Limit Line 12 : Fast Search Limit Found To Most Retard 3 Sweep to Knock Limit AFR Desired DoE AFR Spark at Desired AFR 2 23 : Slow Sweep 1 To Knock-Limit x Start hWorks, Inc. © 2009 The Math Spark Advance DegBTDC 14

- 15. Agenda Introduction Design of experiments Loading and sorting data Building models of engine responses hWorks, Inc. Producing optimized calibrations © 2009 The Math Review R i 15

- 16. Merged 210pt Space Fill Data Ready for MBC Import Space-Fill hWorks, Inc. © 2009 The Math SI_DIVCP_CVIVL_Turbo_I4_Merged_Data.xls 16

- 17. Load 210pt Merged Space Fill Data Space-Fill 1 2 3 6 hWorks, Inc. 4 © 2009 The Math 5 17

- 18. Agenda Introduction I t d ti Design of experiments g p Loading and sorting data Building models of engine responses hWorks, Inc. Producing optimized calibrations © 2009 The Math Review 18

- 19. 1 2 3 5 Finish Model 7 4 6 © 2009 The Math hWorks, Inc. 19

- 20. Review Boundary Model 25 24 hWorks, Inc. © 2009 The Math 20

- 21. Review Final Model 2 6 1 3 4 hWorks, Inc. © 2009 The Math Extrapolation Will Be Prevented 5 By Boundary Model In Optimization Picture Courtesy US AutoParts Later 21

- 22. 6 Review Validation Fits 7 © 2009 The Math hWorks, Inc. 22

- 23. Export Models For Other Users 4 Model Description 5 Input Order hWorks, Inc. Input Order: Brake Torque Value Spark, Speed Load, ICP, ECP, Spark Speed, Load ICP ECP AFR © 2009 The Math 6 Boundary Model Value Values < 0 are within bounds 23

- 24. Export Models For Other Users hWorks, Inc. Use Your Accurate, Fast Torque Model in HIL © 2009 The Math Simulation Model (See HIL_Model.mdl) 24

- 25. Agenda Introduction Design of experiments Loading and sorting data Building models of engine responses hWorks, Inc. Producing optimized calibrations © 2009 The Math Review 25

- 26. 8-Step Process for Producing Optimized Calibrations 1. Import models of engine responses p g p 2. Set up function-models 3. Set up tables and tradeoffs 4. Set up optimization and operating points 5. Run operating-point optimizations 6. Set S t up, initialize, and run sum optimization i iti li d ti i ti hWorks, Inc. 7. Review calibration sensitivity 8. 8 Review and export tables © 2009 The Math 9. Validate calibration with measurements 26

- 27. Import Models of Engine Responses Models are exported 1 directly from the MBC model browser Load SI_DIVCP_CVIVL_AllModels_Complete in MBC Model Browser Start CAGE tool by 2 entering >>cage at hWorks, Inc. MATLAB prompt 3 Click “Import items from Import © 2009 The Math another project” icon 4 6 5 27

- 28. Set Up Tables and Tradeoffs 1 2 4 3 hWorks, Inc. 9 6 7 © 2009 The Math CTRL-V 5 CTRL-C 8 28

- 29. Set Up Optimization and Operating Points 1 2 3 4 hWorks, Inc. 5 6 8 © 2009 The Math 7 29

- 30. Set Up Initialize and Run Sum Optimization Up, Initialize, 1 2 3 5 6 4 hWorks, Inc. 8 © 2009 The Math 9 7 30

- 31. Set Up Initialize and Run Sum Optimization Up, Initialize, 2 1 9 10 hWorks, Inc. 3 © 2009 The Math 7 4 5 6 8 31

- 32. Review Calibration Sensitivity 2 1 3 hWorks, Inc. © 2009 The Math 32

- 33. Review and Export Tables © 2009 The Math hWorks, Inc. 33

- 34. Review and Export Tables 1 hWorks, Inc. © 2009 The Math 2 3 34

- 35. Validate Calibration With Measurements 2 3 hWorks, Inc. © 2009 The Math 1 4 35