GROUP A - POSTER PRESENTATION - M02MAM

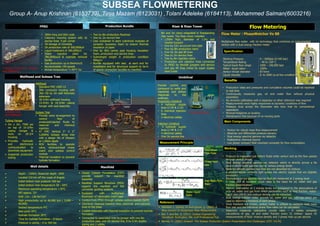

- 1. SUBSEA FLOWMETERING Group A- Anup Krishnan (6153739), Tinja Mazam (6123031) ,Tolani Adeleke (6184113), Mohammed Salman(6003216) Flow Metering Well details Wellhead • Standard FMC UWD 15 • 30in conductor housing with 36in OD by 2in wall thickness extension • 18-3/4in wellhead housing • 13-5/5in & 10-3/4in casing hanger with seal assembly Subsea Tree • Provide valve arrangement to control flow of produced/injected fluids to reservoir and chemical injection • 47 FMC Vertical 5’’ X 2’’ 5,000Psi Subsea Xmas tree with a design life of 20years at 1,500m depth • ROV facilities to operate valve, retrieve/install choke insert and subsea control module • Thermal insulation to prevent hydrate formation Flow Meter : PhaseWatcher Vx 88 Multiphase flow meter with Vx technology that combines an instrumented venturi with a dual energy fraction meter. • Two by 8in production flowlines • One by 2in service line • Line contained in semi cylindrical modules of syntactic buoyancy foam to ensure thermal insulation of pipes • One by 30in carrier pipe housing insulation foam, production and service lines • Submerged weight in production condition 90kg/m • Bundle equipped with sled at each end for installation and for structural support to tie-in of spools connection bundles to manifold. FPSO Production Bundle Riser & Riser Tower Wellhead and Subsea Tree Umbilical Provide control and command to wells and manifolds and deliver chemicals to the wellhead. Production Umbilical • 4 hydraulic supply lines (2 HP & 2 LP) • 6 chemical injection lines • 4 electrical cables Injection Umbilical • 4 hydraulic supply lines (2 HP & 2 LP • 4 electrical cables • One 1in service line 8in and 2in risers integrated in freestanding riser tower. The Riser tower includes: • 1350m high, diameter of 1.5m and neutral buoyant • One by 22in structural core pipe • Four by 8in production risers • Four by 3in gas lift lines • Two by 2in service lines • Two by 8in injection risers • Production and injection lines connected to FPSO by flexible jumpers and service and gas lift lines linked by super duplex steel tubes Manifold • Depth – 1500m, Reservoir depth 2000 • Located 210 km off the coast of Angola • Initial bottom hole pressure 268 bar • Initial bottom hole temperature 58 – 69oC • Maximum operating temperature =70°C • API approx. 32o • GOR 110 – 130 Sm3/m3 • High productivity up to 40,000 b/d ( 5,000 – 40,000) • Seabed temperature 4°C • Wax point 39°C • Hydrate formation 20°C • Time for hydrate formation – 8 hours • Pressure in piping – 0 to 300 bar • Closed Caisson Foundation (CCF) provide support for manifold assembly • Manifold Support Structure (MSS) support the manifold and the connector guiding systems • Equipped with multiphase flowmeter of retrievable insert type • 300m long and 60m wide • Catenary mooring system with 16 anchor lines- 4 per corner • Oil storage of 2mmbbls • Oil production rate of 200,000b/d • Liquid treatment of 300,000b/d • Water injection plant for 390,000bw/d & sulphate removal facility • Gas production up to 8mmcm/d • Accommodate 140 people • Arrival temperature T>40°C for Working Pressure : 0 – 5000psi (0-345 bar) Temperature Rating : - 40 to 1500 C Typical liquid flow range : 1000 – 100,000 bpd Water- liquid ration : 100% Venturi throat diameter : 87.5mm Liquid viscosity : 0. to 2000 cp at line condition Specification Benefits • Production rates and pressures and cumulative volumes could be reported in real time • Continuously measures gas, oil and water flow without physical separation. • No dynamic calibration with a separator or other reference was required • Measurements were highly responsive to dynamic conditions of flow • Pressure drop across the flowmeter less than that for conventional separators • Minimal footprints at location • Maintenance free because of no moving parts Working Main Components • Pressure is measured just before fluids enter venturi and as the flow passes through venturi throat • Dual energy spectral gamma ray detector which is directly across a Ba source which emits gamma rays at various energy levels • Detector detects gamma rays that are not absorbed by mixture • A photomultiplier converts light pulses into electric signals that are digitally processed • Attenuation of the gamma rays by fluid are measured at 2 energy level • A cross plot of resultant count rates is the basis for oil, water and gas fraction determination • Mixture attenuation at 2 energy levels are compared to the attenuations of pure oil, water and gas from which parameters such as fluid fraction, water- liquid ratio (WLR) and mixture density can be extracted. • Dual energy fraction meter provide oil, water and gas hold-ups which are used to determine fractions of each phase. • Once fractions are known, venturi meter is utilised to measure total mass flow rate and the individual phase flow rates can be calculated. • Detectors measures radioactive counts rates – it makes complete calculations of gas, oil and water fraction every 22 millisec- appox 45 measurements of fluid- mixture density and 3 phase hold up per second Reference Tubing Hanger • 5in x 2in, 7500 psi on top of 10-3/4in casing hanger & locks on 18-3/4 housing • Provides hydraulic and electronical communication to downhole equipment • Suspends production tubing • Control from FPSO through subsea control module (SCM) • Distribute chemical injection lines, electrical and hydraulic lines to the trees • Coated externally with thermal insulation to prevent hydrate formation • Connected to associated tree by jumper with one 6in production pipe, one 2in service line, 8 by 0.5in duplex piping and 2 cables Measurement Principle Floating, Production, Storage and offloading Subsea Tree and Wellhead Overview of the Subsea Configuration Umbilical Station Subsea Manifold • Venturi for robust mass flow measurement • Absolute and differential pressure sensors • Dual energy spectral gamma ray detector • Radioactive chemical source • Low power compact field mounted computer for flow computation • Atkinson, i., berard, m. and conort, g. (2005) A New Horizon In Multiphase Flow Measurement. • Bai, Y. and Bai, Q. (2012) Subsea Engineering Handbook. Burlington, MA: Gulf Professional Pub. • Barnay, G. (2002) Girassol: The Subsea Production System Presentation And Challenges. (OTC 14170) Total Mass Flow Rate Phase Hold Ups Gas Mass Flow Rate Water-liquid Ratio