Automatic milk pasteurisation module in 40 characters

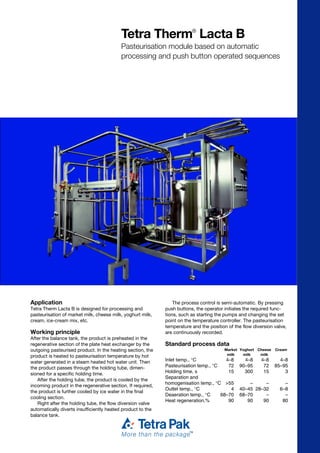

- 1. Tetra Therm Lacta B ® Pasteurisation module based on automatic processing and push button operated sequences Application The process control is semi-automatic. By pressing Tetra Therm Lacta B is designed for processing and push buttons, the operator initiates the required func- pasteurisation of market milk, cheese milk, yoghurt milk, tions, such as starting the pumps and changing the set cream, ice-cream mix, etc. point on the temperature controller. The pasteurisation temperature and the position of the flow diversion valve, Working principle are continuously recorded. After the balance tank, the product is preheated in the regenerative section of the plate heat exchanger by the Standard process data outgoing pasteurised product. In the heating section, the Market Yoghurt Cheese Cream product is heated to pasteurisation temperature by hot milk milk milk water generated in a steam heated hot water unit. Then Inlet temp., °C 4–8 4–8 4–8 4–8 the product passes through the holding tube, dimen- Pasteurisation temp., °C 72 90–95 72 85–95 sioned for a specific holding time. Holding time, s 15 300 15 3 Separation and After the holding tube, the product is cooled by the homogenisation temp., °C >55 – – – incoming product in the regenerative section. If required, Outlet temp., °C 4 40–45 28–32 6–8 the product is further cooled by ice water in the final Deaeration temp., °C 68–70 68–70 – – cooling section. Heat regeneration,% 90 90 90 80 Right after the holding tube, the flow diversion valve automatically diverts insufficiently heated product to the balance tank. TM

- 2. ® Tetra Therm Lacta B – Pasteurisation module based on automatic processing and push button operated sequences Basic design Options Tetra Therm Lacta B is a pre-tested pasteurisation • Design complies with relevant EU directives: module. All components are mounted on a stainless steel – Higher pressure on pasteurised side frame, except for the PHE. – Differential pressure device for display, registration Scope of supply: and alarm • Balance tank (BTD) with level control – Protection sheets on PHE • Centrifugal product feed pump • Automatic product circulation, interlocked with flow • Flow control (mechanical flow controller, frequency diversion and BTD low level switch controlled pump, or homogeniser as timing device) • Automatic cream circulation, interlocked with flow • Free-standing plate heat exchanger (PHE) with diversion and BTD low level switch Teknotext AB cooling, regenerative, and heating sections • Increased/decreased heat regeneration • Holding tube, on top of the module • Automatic outlet and/or intermediate temperature • Hot water unit, incl. PHE, pump, steam valve and trap, control expansion vessel, shut-off valves, etc. • Registration of outlet temperature • Control panel including; relay/regulator control, push • CIP by external circulation, reducing number of buttons, recorder, solenoid valves, and motor starters cleaning circuits • Push button operated sequences • Start/stop buttons for Tetra Alrox Lacta • Automatic pasteurisation temperature control • Capacity control for homogeniser • Automatic flow diversion, interlocked with tempera- • Circular recorder ture failure before and after the holding tube • Remote on/off for homogenisation pressure • Registration of pasteurisation temperature and position of flow diversion valve Additional modules • CIP by internal circulation over BTD • Tetra Alrox Lacta S deaeration module • Tetra Centri separation module • Tetra Alfast automatic standardisation module Installation data • Tetra Alex homogeniser for full or partial Typical footprint for basic module excluding PHE: homogenisation Capacity, l/h ≤ 10 000 > 10 000 • Spiral holding cell for increased holding time Length, mm 2 400 3 000 Width, mm 1 000 1 000 Capacity Height, mm 2 300*) 2 300*) Milk pasteurisation 2 000 – 35 000 l/h *) Higher if holding time more than 15 seconds. Cream pasteurisation 1 000 – 10 000 l/h Simplified flowchart Flow diversion Tetra Alfast standardisation valve module Surplus Hot water unit cream Code PD 63517 en1 00-04 Product IP circulation Tetra Alex Milk out valve Steam homogeniser Tetra Plex By-pass at partial plate heat homogenisation exchanger Whole milk Control panel Tetra Centri Standardised milk separator Tetra Pak Tetra Therm Lacta Holding Skimmilk tube Cream Ice water Hot water © 2000 Tetra Pak Dairy & Beverage Systems AB, Lund, Sweden. Steam Tetra Alrox Diverted flow Flow controller Lacta deaerator Milk in Balance tank Additional modules We reserve the right to introduce design modifications without prior notice. Tetra Pak and Tetra Therm are trademarks belonging to the Tetra Pak Group.