Resume

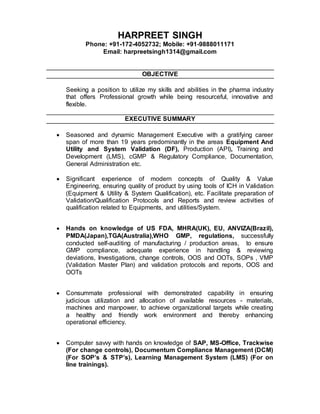

- 1. HARPREET SINGH Phone: +91-172-4052732; Mobile: +91-9888011171 Email: harpreetsingh1314@gmail.com OBJECTIVE Seeking a position to utilize my skills and abilities in the pharma industry that offers Professional growth while being resourceful, innovative and flexible. EXECUTIVE SUMMARY Seasoned and dynamic Management Executive with a gratifying career span of more than 19 years predominantly in the areas Equipment And Utility and System Validation (DF), Production (API), Training and Development (LMS), cGMP & Regulatory Compliance, Documentation, General Administration etc. Significant experience of modern concepts of Quality & Value Engineering, ensuring quality of product by using tools of ICH in Validation (Equipment & Utility & System Qualification), etc. Facilitate preparation of Validation/Qualification Protocols and Reports and review activities of qualification related to Equipments, and utilities/System. Hands on knowledge of US FDA, MHRA(UK), EU, ANVIZA(Brazil), PMDA(Japan),TGA(Australia),WHO GMP, regulations, successfully conducted self-auditing of manufacturing / production areas, to ensure GMP compliance, adequate experience in handling & reviewing deviations, Investigations, change controls, OOS and OOTs, SOPs , VMP (Validation Master Plan) and validation protocols and reports, OOS and OOTs Consummate professional with demonstrated capability in ensuring judicious utilization and allocation of available resources - materials, machines and manpower, to achieve organizational targets while creating a healthy and friendly work environment and thereby enhancing operational efficiency. Computer savvy with hands on knowledge of SAP, MS-Office, Trackwise (For change controls), Documentum Compliance Management (DCM) (For SOP’s & STP’s), Learning Management System (LMS) (For on line trainings).

- 2. CAREER MILESTONES Successful association with Sun Pharmaceutical Industries Limited (erstwhile Ranbaxy Laboratories Limited) for more than 19 years. Executed diverse responsibilities in various departments including, Validation (DF equipments and utilities and systems), Production (API), Quality Assurance, Training and Development through LMS, Regulatory Compliance Audits including US FDA,MHRA,EU,ANVIZA,PMDA,TGA, WHO GMP and Safety Initiatives and Documentation. Appreciated for outstanding performance and rewarded Excellence Award in Ranbaxy Laboratories for improving the quality, cost savings, inventory liquidation and reducing cycle time in 2009. Conducted Self-Auditing of Manufacturing / Production Areas, to ensure GMP compliance. Handled and reviewed deviations, investigations, change controls, VMP (Validation Master Plan), validation protocols, validation reports, SOP, OOS and OOTs. PROFESSIONAL EXPERIENCE AND ACCOMPLISHMENTS Employed as production chemist in Feb.1997 and now as senior executive in Sun Pharmaceutical Industries Limited (erstwhile Ranbaxy Laboratories Limited). During this period of job I had worked in plants of sterile (Bulk API), non sterile (Bulk API) and dosage form(OSD). In Dosage Form (OSD) - (2012-Till date) I am currently handling validation activity related to all equipment and utilities (HVAC System, Water System, Compressed Air System, Nitrogen Air System).And performing various activities related to validation such as URS (User Requirement Specification) DQ (Design Qualification) RA (Risk Assessment) cGXP IA (Impact Assessment) IQ (Installation Qualification) OQ (Operational Qualification) PQ (Performance Qualification) FQ (Facility Qualification) TM (Temperature Mapping) Successfully completed the validation activity of two projects –New Microbiology lab and New Solvent Warehouse establishments. Preparation of URS for the equipment / System. Review of design specification offered by vendor and compares it with URS and preparing DQ. Preparation of RA for the equipment / System

- 3. Preparation of GXP Impact Assessment for the equipment and system to categories as Direct, Indirect, No Impact Category. Preparation and Approval and Execution of validation protocol and summary report of IQ, OQ, PQ. Preparation and Approval and Execution of validation protocol and summary report of FQ and TM. Performing Periodic Performance Verification (PPV) of the equipments and system as per their schedule timing to have equipment and system in validated state of control. Preparing PPV calendar and PPV report matrix on yearly basis. To coordinate and interact with vendor, engineering department, user department and project team for the timely completion of the validation activities and resolve of technical issues. To ensure compliance of cGMP and GDP. Preparation of Master Validation Plan for the site Equipment validated-HVAC system, RLAF(Dispensing & Sampling Booth), LAF, Water System, Compressed Air System, Area Qualification, Capsule Filling Machine, Tablet Compression Machine, Cold Room, Sifter, Multimill, Inverted Mode Air Jet Bottle Cleaning Machine, Domino Printer(Ink Jet Printer), Blister Sealing Machine, Strip Sealing Machine, Rapid Mixer Granulator, FBD, Coating Machine, Liquid Filling Machine, Roll Compactor, Dedusting Tunnel, Sticker Labelling Machine, Checkweigher, Dose Cup Capping Machine, Homogenizer/Colloidal Mill, Tablet Printing Machine, Induction Sealing Machine, Filter Cleaning Station and many more… I am also looking after and imparting the training through Learning Management System (LMS) to the users of the plant. Training related to all kind of SOP (Standard Operating Procedure) and cGMP training I am LTC for LMS at site, learning software supported by M/s SumTotal. Collate all departments Master Training Need Matrix (MTNM) for preparing location MTNM. Configuring and Uploading training material and task in LMS. Auditing and compliance of training at site. Creation of Job Roles in LMS as per MTNM. Creating learning activities/curriculum in the system as new activity or for revised version and categorized under SUN specific, Regulatory, Developmental and Activity based SOP’s. Assigning curriculum to Job Role as per MTNM. Associating Job Role to the users as per MTNM. Training records and available in the system at all times on real time basis. Monitoring Training Compliance – User Wise / Activity Wise. Various reports are generated such as :- 1. Completion and Compliance Reports a) Learning activity SOP allocation to departments

- 4. b) Department wise Matrix Completion Reports c) Department wise Training allocation and completion (Graph) with detail report. d) SOP wise department employee wise training completion. e) Job Role wise training compliance. f) Location wise training completed during a period g) Location wise Manday’s summary during a period. h) Location wise Manday’s detail report during a period. i) Compliance reports. 2. LMS reports a) List of Job Roles b) List of Department / Functions c) List of learning Activities and Topics d) Employees Master e) Trainer Qualification Reports 3. MTNM Reports 4. Impact Assessment Reports 5. List of Unsuccessful Attempts / Failure Attempts and many more…. I have actively participated in getting the ISO 14001 and OSHAS for the site. In Non Sterile Production (API Bulk) - (2000-2011) I have involved in manufacturing of cefuroxime axetil amorphous chemical route and spray dried route. I have also handled manufacturing of cefditoren Pivoxil Spray Dried Premix. I had worked in plant setup of spray drying at project stage in our organization in the year 2005 Review of batch production records (BPR) and in process test. Involved in managing operations, documentation, quality assurance, and planning activities along with a team of 20 members. Manage the production planning and control activities, setting up production targets and handling plant operations to ensure timely completion of production targets within the defined time and cost parameters. Played an important role in effective resource planning and utilization, reducing waste for enhancing productivity and profitability. Involved in maintaining records as per GMP requirements, and self / internal auditing of manufacturing / production areas to ensure GMP compliance and quality commitments. Ensure adherence to various SOPs, STP & SCPs Prepare, Review & implement MPR.

- 5. Follow up mechanism to handle and successfully close a non- conformance. Initiation of Change Control and their closure Participated in failure investigation (Out of specification). Conducted root cause analysis of the problem and identification of major root causes and their remedies. Handled & reviewed deviations, change controls, OOS & OOT. Qualification of HVAC (Heating ventilation and air conditioning system). Validation of production systems like drying validation, blending validation. Responsible for installation Qualification, Operational, Qualification, Performance Qualification of systems. Ensuring that the Quality Management System is maintained in accordance with ICH Guideline. Drive the continuous improvements in operational qualities, setting up controls, reviews, and implementation of corrective actions. People Engagements & effectives on quantity improvements projects. In Sterile Production (API Bulk) - (1997-1999) I have involved in manufacturing of sterile ceftriaxone sodium and sterile cefatoxime, acid. Autoclave qualified with respect to IQ, OQ, PQ and know how to operate the equipment, used for sterilizing filter cartridges(used for sterile filtration),Rubber bungs, garments. Dry Heat Sterilizer (DHS) qualified with respect to IQ, OQ,PQ and know how to operate the equipment. Use for sterilizing Aluminium containers, Caps, foil and sampler etc. WFI (Water for injection) qualified. Pure steam generator qualified. Filter integrity testing by Bubble point method by Millipore equipment. Versaport-10 particle counter operated used for counting particle count on monthly basis as per AHU classification class A, B, C, D. HVAC system of sterile area qualified. Hanging Laminar Air Flow (LAF) for class A qualified. Preparation and approval of validation Protocol and Reports. Review of batch production records and in process test.

- 6. PROJECTS HANDLED 1. New Microbiology Lab made operational at OSD site Following activities carried out to related with the validation/qualification activities :- Made Use Requirement Specification (URS) of the Heating Ventilation Air Conditioning (HVAC) to be procured for the project. Installation Qualification (IQ) of the HVAC system performed. Operational Qualification (OQ) of the HVAC system performed. Performance Qualification (PQ) of the HVAC system performed, covering parameters such as:- Air Velocity and Air Changes Per Hour Filter Integrity Test Differential Pressure Monitoring Test Non-Viable Particle Count Test Recovery of Non-Viable Particle Count Test Air Flow Visualization Test Temperature & Relative Humidity Monitoring Test Recovery of Temperature & Relative Humidity & Differential Pressure Test Viable Count Test ( Microbiological Monitoring Test) Made User Requirement Specification (URS) for the Facility. Performed Facility Qualification/Area Qualification of the facility covering parameters such as:- Rooms Dimensions Material & Personnel flow Floor-MOC, Surface finish Doors-MOC, Size, Interlock Coving-MOC, Surface finish Ceiling-MOC, Surface finish Vision Panel-MOC, Size Drains-Air Break, Cover Walls-MOC, Paint colour, Paint Type, Surface finish Steam, Pure Steam, Compressed Air, Industrial Gasses Electrical & Associated-Number of lights, Illumination level, single/three phase etc HVAC-Supply & Return grill number, ACPH, Temperature, Relative Humidity, Differential Pressure, HEPA filter leak test, Particle count, Microbiological Monitoring Water- Potable, Purified, Water for injection 2. New Solvent Warehouse made operational at OSD site In similar way as above another Project of solvent Warehouse was handled.

- 7. 3. New Spray Dryer Plant- From ALFA LAVAL made operational at API Bulk site I have handled the project of plant set up of spray dryer Following activities carried out during the project:- Installation Qualification (IQ) of the equipment performed. Operational Qualification (OQ) of the equipment performed. Performance Qualification (PQ) of the equipment performed, covering parameters such as:- Taken trails with product Cefuroxime Axetil at different Inlet & Outlet Temperature setting of the spray Dryer . At various RPM of the Supply blower and the Exhaust blower for the optimisation of the speed. To check & verify the RPM of the Atomiser To check the Amorphous nature of the product, it should not be in crystalline nature Spray Drying is performed to convert the crystalline form of the product into Amorphous form. SPECIALZED TRAINING Gone through extensive 400hrs of training at karnataka antibiotics and pharmaceuticals limited Bangalore in following area – Dry powder parentrals and non parentrals and small volume parentrals and quality control and store management. Training on fire fighting with advanced fire fighting techniques. ACADEMIC AND PROFESSIONAL CREDENTIALS Bachelor of Pharmacy (B’PHARMA) from Bangalore University. Audits Handled US-FDA – 1998, 2000, 2003, 2007, 2008 TGA – Australia – 2000, 2004 Germany Audits – 2005, 2007 WHO – GMP Audits – 1999, 2003, 2007, 2008, 2014 PERSONAL DETAILS Address : H.No.1314, Sector-68, Mohali (Punjab), Pin-160062, India Date of Birth: 20th April 1972 Marital Status: Married Blood Group: O-ve