Sme248 january-2007-0 reiff injection molding tour

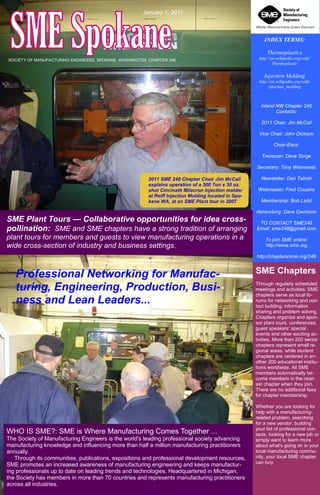

- 1. January 1, 2011 INDEX TERMS: Thermoplastics SOCIETY OF MANUFACTURING ENGINEERS, SPOKANE, WASHINGTON CHAPTER 248 http://en.wikipedia.org/wiki/ Thermoplastic Injection Molding http://en.wikipedia.org/wiki/ injection_molding Inland NW Chapter 248 Contacts: 2011 Chair: Jim McCall Vice Chair: John Dickson Chair-Elect: Treasurer: Dave Sorge Secretary: Tony Wisnewski 2011 SME 248 Chapter Chair Jim McCall explains operation of a 300 Ton x 30 oz. shot Cincinatti Milacron Injection molder at Reiff Injection Molding located in Spokane WA, at an SME Plant tour in 2007 Newsletter: Dan Tabish Webmaster: Fred Cousins Membership: Bob Ladd Networking: Dave Davidson SME Plant Tours — Collaborative opportunities for idea crosspollination: SME and SME chapters have a strong tradition of arranging plant tours for members and guests to view manufacturing operations in a wide cross-section of industry and business settings. TO CONTACT SME248 Email: sme248@gmail.com To join SME online: http://www.sme.org http://chapters/sme.org/248 The Lean Networking for ManufacProfessionalJourney at Kimball Office Products, Post Falls, ID. Be there and turing, Engineering, Production, Busisee it with SME Chapter 248 for another ness and Lean Leaders... in a series of SME Lean Benchmark Tours—Wed., Sept. 17, 2008 at 6:00 PM SME Plant tours are networking opportunities that demonstrate the power of analogizing. Their business may be different from yours, but there are important things you may learn from what they do and how they do it, especially in a lean context. WHO IS SME?: SME is Where Manufacturing Comes Together ... The Society of Manufacturing Engineers is the world's leading professional society advancing manufacturing knowledge and influencing more than half a million manufacturing practitioners annually. Through its communities, publications, expositions and professional development resources, SME promotes an increased awareness of manufacturing engineering and keeps manufacturing professionals up to date on leading trends and technologies. Headquartered in Michigan, the Society has members in more than 70 countries and represents manufacturing practitioners EDITORS NOTE: for lean aficionados only, this docuacross all industries. ment has been formatted to an 11 x 17 or A3 dimension... SME Chapters Through regularly scheduled meetings and activities, SME chapters serve as local forums for networking and contact building, information sharing and problem solving. Chapters organize and sponsor plant tours, conferences, guest speakers' special events and other exciting activities. More than 200 senior chapters represent small regional areas, while student chapters are centered in another 200 educational institutions worldwide. All SME members automatically become members in the nearest chapter when they join. There are no additional fees for chapter membership. Whether you are looking for help with a manufacturingrelated problem, searching for a new vendor, building your list of professional contacts, looking for a new job or simply want to learn more about what's going on in your local manufacturing community, your local SME chapter can help

- 2. INJECTION MOLDING FUNDAMENTALS Reiff Injection Molding — Success from Adaptation... Case History/Plant Tour – Spokane, Washington., Jan. 23, 2007 by Dave Davidson. Photos by Ray McDied Tour Organized by Society of Manufacturing Engineers, Spokane, WA Chapter 248 Injection molding is the most popular method of making plastic molded parts. Jim and J. McCall own and operate Reiff Injection Molding Co., a manufacturer of plastic injection molded parts originally established in 1979 in Walla Walla, WA. The company moved to Spokane, WA in 1999 and recently moved from its University Road operation to larger facilities located at 131 N. Pittsburg close to the Altamont exit on I-90. The company runs four different plastic injection molding machines, and manufactures parts for a variety of industries including the medical, telecom, irrigation and recreation industries. Injection Molding has the advantage of quality parts produced in high production runs at low cost. In Injection Molding normally small solid plastic pellets are put into a hopper on the injection molding machine. The plastic travels through a long cylinder known as a barrell. The barrell has an auger in it that is known as a screw. While the plastic pellets are traveling through the barrell they are heated and melted. At the appropriate moment the molten plastic is rapidly "injected" at high pressure into a precision closed mold. See the graphic on our home page. The plastic then cools and solidifies in the mold. The mold then opens and the plastic part or parts are ejected from the mold. Plastic Injection Molding cell at Reiff Injection Molding Inc., plant tour attendees watch as Jim and J. McCall explain operations of the four machines in the cell including: (1) BOY 25 Ton x 1 oz. (2) Toshiba 85 &on x 3.2 oz. (3) Toshiba 190 Ton x 10 oz. (4) Cincinnati- Milacron 300 Ton x 30 oz Cycle times for producing parts can typically be from 40 to 60 seconds. Plastic table ware can run as fast as 4 seconds. Challenges: Like many American manufacturers, Reiff has faced serious challenges due to the outsourcing of products overseas. The company faced a severe test when one of its major customers, a subsidiary of a Fortune 500 firm decided it was going to start outsourcing product from India. This change was particularly unsettling as it would mean not only loss of one of the company's largest customers, but the loss of the company facilities as well, as the large customer had been providing facilities for the plastic injection molding Most molds are single cavity (produces one part each cycle). If the mold has 200 cavities (makes 200 parts in one cycle) and cycles in 4 seconds then the production is 200 parts in 4 seconds or 3200 parts a minute. If you notice the number on the back of plastic table ware next time you are at a fast food place, that tells you which cavity the part came from. The little round circles are from the ejector pins. Can you figure out where the plastic was injected into the cavity? That is called the gate and is normally at the end of the handle. Jim McCall President Reiff Injection Molding reiffinjectionmolding.com Reiff Molding has developed unusually close relationships with customers and provides inhouse custom engineering and specially tailored production and inventory programs that anticipates customer needs and requirements. SME Chapter 248 members listen as owners Jim and Jay McCall explain their operation as well as the basic principles involved in transforming thermoplastic granular feedstock used as the basic raw material into molded products by carefully controlled heat and pressure

- 3. Reiff Injection Molding — Success from Adaptation... Case History/Plant Tour – Spokane, Washington., Jan. 23, 2007 by Dave Davidson. Photos by Ray McDied, Tour Organized by Society of Manufacturing Engineers, Spokane, WA Chapter 248 Plastic Injection Molding cell at Reiff Injection Molding Inc., plant tour attendees watch as Jim and J. McCall explain operations of the four machines in the cell including: (1) BOY 25 Ton x 1 oz. (2) Toshiba 85 &on x 3.2 oz. (3) Toshiba 190 Ton x 10 oz. (4) Cincinnati- Milacron 300 Ton x 30 oz ___________________________________________________________ BELOW: J. McCall explains operation of the computer controls on the company’s TOSHIBA 190 Ton x 10 oz. injection molding machine to Jeff Dornerberg, an associate professor in the Mechanical Engineering Dept. at Eastern Washington University. The university located in Cheney, WA. was a recipient of an SME Education Foundation grant ($220,000.00) used in the construction of it’s new computer science facility. (Cont’d from page 2) operation for its own convenience. The company has not only survived but has successfully expanded its business through utilizing its internal strengths to provide exceptional customer service that competitors find difficult to duplicate. As a family business, father Jim McCall has a strong process and operations background working with Whirlpool Corporation in Michigan after receiving a master’s degree in engineering from the University of Michigan. Son, J. McCall, has a strong plastic materials background with a degree from Western Washington University. Together, they are in a position to not only offer manufacturing services but custom engineering development and materials selection advice to customers who need this kind of process development assistance to take parts from prints in the design stage and turn them into reality. They have locked in customer relationships not only by being a manufacturing source for plastic molded products, but by also being a design and engineering resource to customers who have new product in the formative stage. They are especially adept at assisting customers in modifying or tweaking original designs in such a way to make actual production operations more practical, feasible and cost efficient. As an example of this, Jim McCall, explained an especially challenging design and operational problem the company had been faced with recently involving “puffer nozzles”. This molded component is part of a sophisticated quality assurance system used in the food and produce industry. As items are passed down the length of an inspection conveyor they are analyzed by an optical/video system which can identify defective or nonconforming items. Once an identification has been made the system will remove the offending item from the production stream by actuating the “puffer nozzle” which then directs a “puff” or “blast” of high velocity air at the defective piece as it comes off the conveyor, segregating it from acceptable product. The “puffer nozzle” is a challenging product for the plastic injection molding process where products are typically designed with a specific taper to promote ease of ejection from the mold at the end of the injection cycle. On this part the internal orifice had to be designed with a taper opposite to that which would be normal for ejection purposes in order to produce sufficient velocity in the air puff used to remove the piece from the conveyor stream. ____________________________________________ SME Injection Molding Technical Group www.sme.org/injectionmolding This group provides an opportunity for SME members involved in plastic injection molding to collaborate and exchange information related to their field. This team has been actively engaged in the development of resources to assist other injection molders, including a variety of Web resources and technical conference sessions. Tech Group Activities Featuring proven industry tips and techniques, submitted by numerous industry professionals, on a variety of plastics manufacturing topics, including materials, design, tooling, processing, assembly and finishing. Injection Molding Webinars Throughout the years, the Injection Molding Tech Group has presented and/or participated in presentations (webinars) on injection molding-related topics. These webinars were typically one hour in length and included an interactive question and answer period. Monthly Conference Calls Is there a particular injection molding/plastics manufacturing topic you want to learn about? Do you have information to share with other SME members? We want to hear from you! Roundtable discussions are held on a regular basis through one-hour teleconferences. This is a great opportunity to connect with other SME members with similar manufacturing interests and challenges and learn from each other. To get involved, or to suggest a discussion topic, e-mail membership@sme.org.