Servo drive application for box labeling

•

0 recomendaciones•980 vistas

Using the Tuba & Cornet digital servo drives, Elmo Motion Control has implemented a unique ECAM-based solution for managing an application that prints labels on boxes moving at irregular intervals along a conveyor.

Denunciar

Compartir

Denunciar

Compartir

Descargar para leer sin conexión

Recomendados

Recomendados

Más contenido relacionado

Destacado

Destacado (9)

5º Básico A: Informativo Nº 29: Semana del 03 al 07 de octubre

5º Básico A: Informativo Nº 29: Semana del 03 al 07 de octubre

Why people are wanting to gain permanent residency in australia

Why people are wanting to gain permanent residency in australia

Pensioenkas Brussels parlement heeft tekort van 37,5 miljoen

Pensioenkas Brussels parlement heeft tekort van 37,5 miljoen

Similar a Servo drive application for box labeling

In spinning industry, AC-drives are needed to rotate in synchronized speed to achieve quality

product. Because of the quick evolution of manufacturing processes, the demand for flexible automation

systems is on the rise. To meet these, distributed motion control architecture based on intelligent drives and

field bus communication tends more and more to replace the traditional solutions. Drive synchronization is

necessary in industries where minor difference in rotary movement make major difference in product quality.

Using CAN (Control Area Network) protocol we can drive multiple motor in synchronization with minimum

transmission gap. A control area network (CAN) based multi-motor synchronized motion control system with

an advanced synchronized control strategy is proposed. The strategy is to incorporate the adjacent crosscoupling

control strategy into the sliding mode control architecture. In this project we are going to

synchronize multiple AC motors using CAN protocol.[IJET-V2I2P16] Authors: Jariwala Hiren, Patel Chintan, Prasad Kuldip, Shukla ...![[IJET-V2I2P16] Authors: Jariwala Hiren, Patel Chintan, Prasad Kuldip, Shukla ...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![[IJET-V2I2P16] Authors: Jariwala Hiren, Patel Chintan, Prasad Kuldip, Shukla ...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

[IJET-V2I2P16] Authors: Jariwala Hiren, Patel Chintan, Prasad Kuldip, Shukla ...IJET - International Journal of Engineering and Techniques

Similar a Servo drive application for box labeling (20)

02-Chapter_2_Robot_Work_Cell_Design_and_Control_Final.pdf

02-Chapter_2_Robot_Work_Cell_Design_and_Control_Final.pdf

CONCEPT AND WORKING OF WILD (Wheel Impact Load Detector)

CONCEPT AND WORKING OF WILD (Wheel Impact Load Detector)

ROBOT HYBRID AND FORCE CONTROL IN MULTI-MICROPROCESSOR SYSTEM

ROBOT HYBRID AND FORCE CONTROL IN MULTI-MICROPROCESSOR SYSTEM

International Journal of Engineering Research and Development (IJERD)

International Journal of Engineering Research and Development (IJERD)

[IJET-V2I2P16] Authors: Jariwala Hiren, Patel Chintan, Prasad Kuldip, Shukla ...![[IJET-V2I2P16] Authors: Jariwala Hiren, Patel Chintan, Prasad Kuldip, Shukla ...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

![[IJET-V2I2P16] Authors: Jariwala Hiren, Patel Chintan, Prasad Kuldip, Shukla ...](data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7)

[IJET-V2I2P16] Authors: Jariwala Hiren, Patel Chintan, Prasad Kuldip, Shukla ...

Más de Elmo Motion Control

Más de Elmo Motion Control (20)

Servo drive application for print inspection | ElmoMC

Servo drive application for print inspection | ElmoMC

Flying vision target position corrections | ElmoMC

Flying vision target position corrections | ElmoMC

Boosting the Performance LED Semiconductor Die-Bonding Machine

Boosting the Performance LED Semiconductor Die-Bonding Machine

Motion control application cardiac imaging scanner

Motion control application cardiac imaging scanner

Servo Drives For a Wide Range of AC/DC Voltages | ElmoMC

Servo Drives For a Wide Range of AC/DC Voltages | ElmoMC

Solution for Industrial Printing & Textile Machines | Elmo Motion Control

Solution for Industrial Printing & Textile Machines | Elmo Motion Control

Último

Último (20)

Apidays New York 2024 - The value of a flexible API Management solution for O...

Apidays New York 2024 - The value of a flexible API Management solution for O...

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

Powerful Google developer tools for immediate impact! (2023-24 C)

Powerful Google developer tools for immediate impact! (2023-24 C)

ProductAnonymous-April2024-WinProductDiscovery-MelissaKlemke

ProductAnonymous-April2024-WinProductDiscovery-MelissaKlemke

Repurposing LNG terminals for Hydrogen Ammonia: Feasibility and Cost Saving

Repurposing LNG terminals for Hydrogen Ammonia: Feasibility and Cost Saving

Web Form Automation for Bonterra Impact Management (fka Social Solutions Apri...

Web Form Automation for Bonterra Impact Management (fka Social Solutions Apri...

AWS Community Day CPH - Three problems of Terraform

AWS Community Day CPH - Three problems of Terraform

Boost Fertility New Invention Ups Success Rates.pdf

Boost Fertility New Invention Ups Success Rates.pdf

Strategize a Smooth Tenant-to-tenant Migration and Copilot Takeoff

Strategize a Smooth Tenant-to-tenant Migration and Copilot Takeoff

TrustArc Webinar - Unlock the Power of AI-Driven Data Discovery

TrustArc Webinar - Unlock the Power of AI-Driven Data Discovery

EMPOWERMENT TECHNOLOGY GRADE 11 QUARTER 2 REVIEWER

EMPOWERMENT TECHNOLOGY GRADE 11 QUARTER 2 REVIEWER

Apidays Singapore 2024 - Scalable LLM APIs for AI and Generative AI Applicati...

Apidays Singapore 2024 - Scalable LLM APIs for AI and Generative AI Applicati...

Polkadot JAM Slides - Token2049 - By Dr. Gavin Wood

Polkadot JAM Slides - Token2049 - By Dr. Gavin Wood

Automating Google Workspace (GWS) & more with Apps Script

Automating Google Workspace (GWS) & more with Apps Script

Servo drive application for box labeling

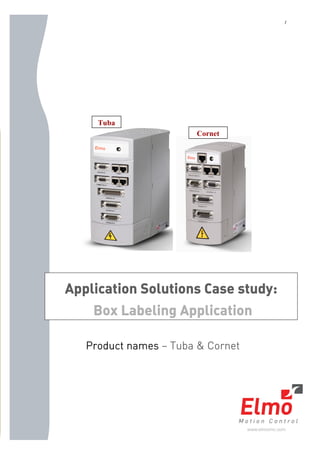

- 1. 1 Tuba Cornet Application Solutions Case study: Box Labeling Application Product names – Tuba & Cornet

- 2. 2 Using the Tuba & Cornet digital servo drives, Elmo Motion Control has implemented a unique ECAM-based solution for managing an application that prints labels on boxes moving at irregular intervals along a conveyor. The Challenge When automating a labeling application using a printing roller, one needs to take into account the speed of the mechanism moving the item to be labeled, in conjunction with the rotation speed of the labeling roller. These two factors are independent of the distance between two consecutive boxes, and between a single box and the labeling roller. In the case presented here, a conveyor carries boxes towards a roller assembled above the conveyor. An optical device mounted on the edge of the conveyor in front of the roller captures an incoming box and “notifies” the drive controlling the roller to prepare for printing the label. The roller is engaged, the label is printed and the roller is subsequently disengaged until notified of the next incoming box. For this scenario, Elmo Motion Control devised a master-slave configuration in which the Tuba digital drive serves as the master that controls the conveyor. The labeling roller is the slave, driven by the Cornet. The arrival of each box is indicated by a high-speed digital input that captures the master location and sends the signal to the slave (Cornet). Upon receipt of that signal, the roller is homed to the position of the first label and, as the box arrives at the appropriate place, it is engaged and prints the label. The roller disengages after the print, unless another capture signal has been sensed and another box arrives for printing. The roller contains two labeling matrices, so that an entire roller cycle prints labels on two boxes. The challenges in such an application arise from the fact that the boxes on the conveyor do not travel towards the labeling roller at regular intervals, requiring a mechanism for disengaging the roller on-the-fly and then re-engaging it after it has been rotated to the

- 3. 3 proper position for printing the next label. Furthermore, this type of labeling procedure requires on-going adjustments of the labeling roller speed to that of the conveyor speed. To achieve synchronization, the absolute position of the roller (slave) must be adjusted after each print cycle in order to prepare for the subsequent one. At the same time, the conveyor (master) motor position must roll over (start a new revolution) without losing synchronization with the position reference of the roller. Elmo's Solution In order to synchronize the roller speed with the conveyor speed for printing, so that the box arrives at the roller when the roller has been rotated to the right print point, a preprogrammed ECAM table was created and installed in the slave drive, to be used as a reference table for positioning the roller for printing. The ECAM table describes the nonlinear trajectory of the roller, ensuring that the roller speed exactly matches that of the conveyor when the box reaches the print location. To achieve this, the Cornet drive counts in modulo when it exceeds the slave-roller position limits (a full revolution), maintaining the velocity command as the motor begins a new revolution. The home location for the roller can be either the absolute home location or the modulo rollover location of the roller, which is half of the roller cycle (for printing the second label). This depends on if one or two boxes arrive at the same time. The actual home position for start of printing is therefore determined by the offset of the master capture, which determines at what step in the ECAM table to begin the slave trajectory. The trajectories remain the same, regardless of conveyor location and roller start position. Recording the Slave Trajectory This record of the slave Position command demonstrates the roller trajectory when one and then two boxes arrive at the printing area. The slave (roller) is a 32,000-count motor. The printing area occurs between locations 10,000 and 14,000. After printing, the slave continues to its home location according to the software relative command that it receives. Sample trajectory of slave roller Upon receipt of a software command, the slave accelerates from point 1 to point 2, printing a label on the box. Point 3 indicates the location at which the first label is fully printed, at which point the slave continues with a point-to-point movement to point 4, awaiting the arrival of the next box.

- 4. 4 The next box arrival is captured at point 5. The roller begins to accelerate again and begins printing at about -14,000 counts. While this box is being printed, another box arrival is captured and at point 6, an immediate follower engagement is performed in order to print the third box. Each print takes 14,000 counts and the homing takes 2,000 counts more. As can be seen from the graph, the trajectories are the same regardless of conveyor location and roller start point, and if one or two boxes arrive at the same time. Consistent and Reliable, at Any Speed Thanks to the ECAM-based operation of the master-slave configuration and the ability to engage/disengage the roller motion on-the-fly, the box labeling application operates smoothly despite variable speeds of the conveyor and different distances between boxes. The label printing proceeds exactly as required for any number of boxes, arriving at irregular intervals. It’s a very accurate solution for what could be a complicated and erratic printing process. Tuba & Cornet Digital Servo Drives The Tuba & Cornet - digital servo drives feature high-quality servo performance aligned with sinusoidal vector control. These drives are highly flexible, operating in a range of modes: current, velocity, position and advanced position (PVT, PT, ECAM and Dual Loop). Very efficient networking is accomplished via CANopen. Both drives are very compact and connect directly to the mains power source (up to 480 VAC). The Tuba drive delivers up to 10 KW of power; the Cornet, up to 2.5 KW. The drives can be manually or automatically tuned using Elmo’s Composer application for drive setup, configuration, tuning, logging and analysis. For more information on Elmo: Ace Pillar Co. Ltd. West 10 Avenue,Tianjin Airport Industrial Park TIANJIN, 300308 China Tel: +86-22-23556000 Fax: +86-22-23556368 chen.timothy@acepillar.com.cn