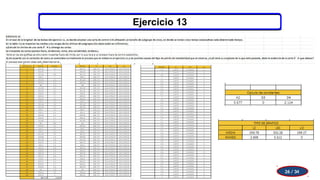

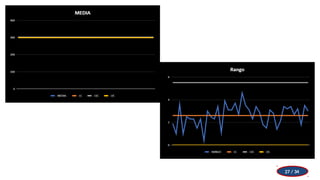

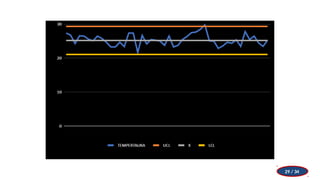

Uses control charts for process stability.

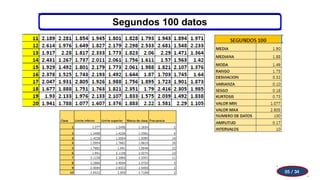

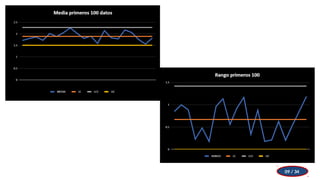

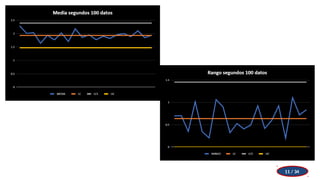

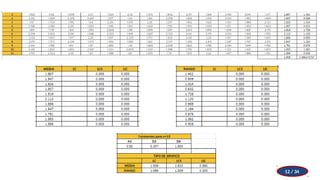

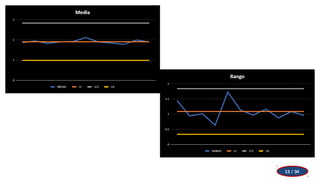

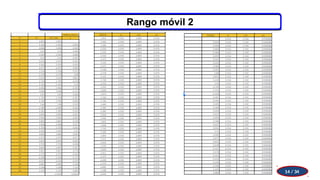

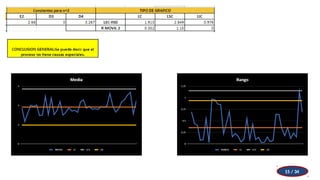

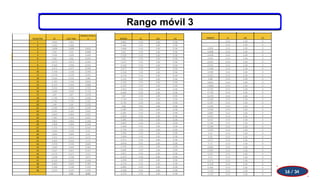

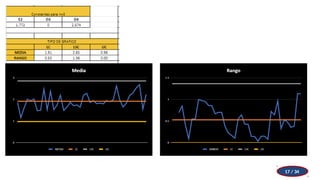

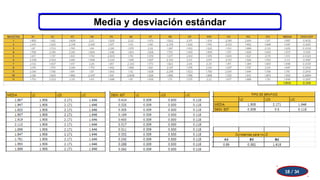

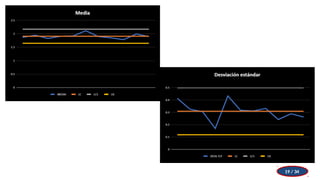

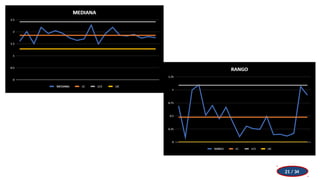

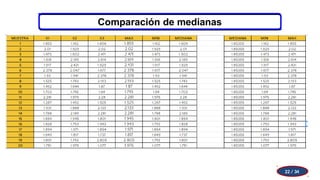

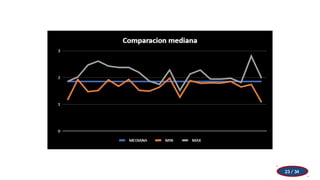

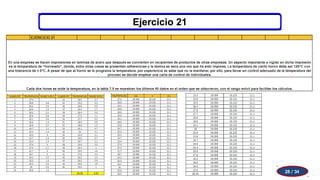

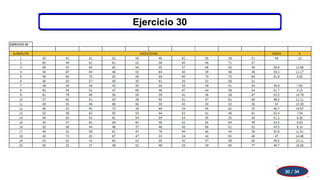

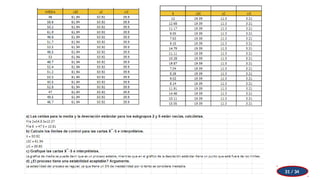

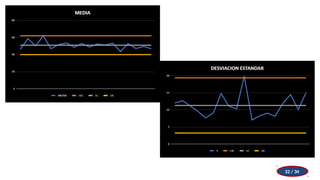

Charts track means, ranges, and standard deviations.

Distinguishes between common and special cause variation.

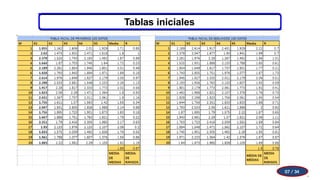

A process is stable if data is within control limits.

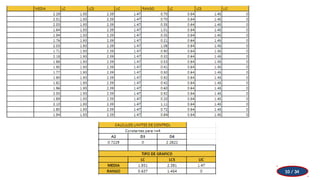

Control limits are calculated as mean ± 3 standard deviations.

Different charts (X̅-R, X̅-S, I-MR) for different applications.

Pre-control is used for startup, not for poor capability processes.